Battery cabinet current sampling accuracy

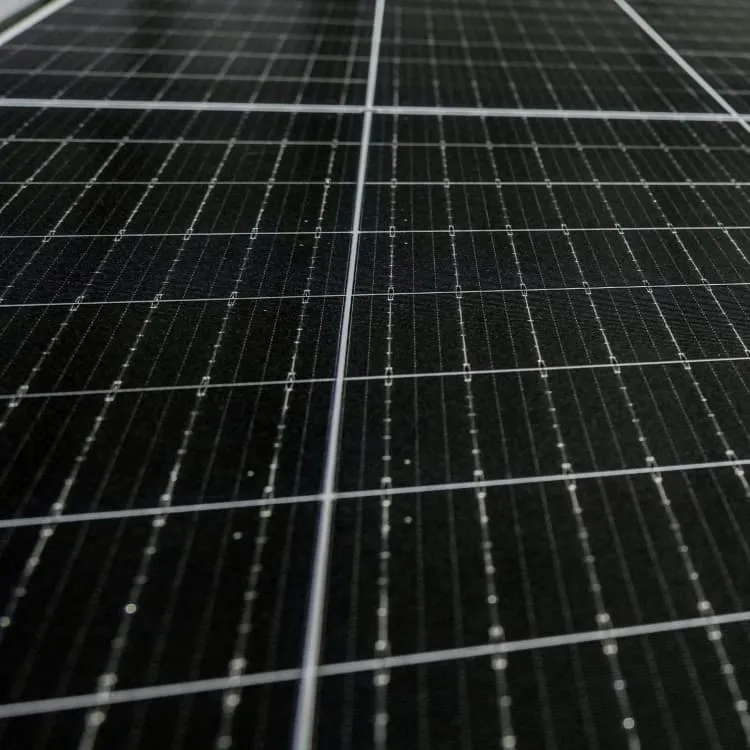

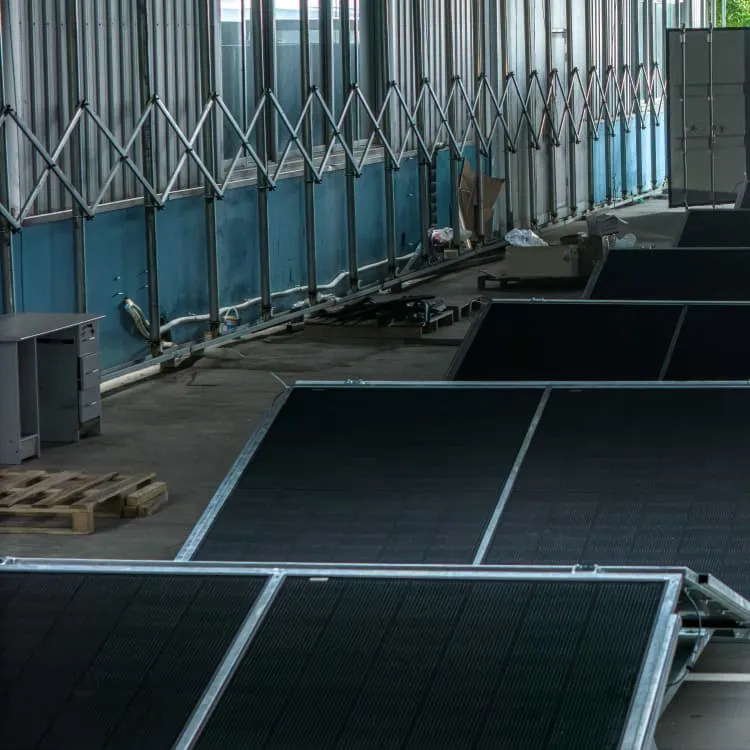

Welcome to our dedicated page for Battery cabinet current sampling accuracy! Here, we have carefully selected a range of videos and relevant information about Battery cabinet current sampling accuracy, tailored to meet your interests and needs. Our services include high-quality solar container products and containerized PV solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to Battery cabinet current sampling accuracy, including cutting-edge solar container systems, advanced containerized PV solutions, and tailored solar energy storage applications for a variety of industries. Whether you're looking for large-scale utility solar projects, commercial containerized systems, or mobile solar power solutions, we have a solution for every need. Explore and discover what we have to offer!

Top 10 Battery Test Equipment Brands: Comparison and

The battery testing solutions designed by Sinexcel-RE offer remarkable voltage accuracy, with a precision of up to ±0.02% F.S., current accuracy of up to ±0.05% F.S., fast

Request Quote

UNICO BATTERY CELL TESTERS

Voltage, current, temperature, analog-in and analog-out measurement per channel* Up to 4096 (12.5A channels) or 8192 (300A channels) samples per snapshot per signal Configurable

Request Quote

A High Precision Current Sampling Circuit with Rail-to-Rail

Current information in the lithium-ion battery charging system is important for system control and can be used for overload protection, constant current control

Request Quote

Current Shunt &Voltage Measurement Reference Design for

This design provides a unique solution of current monitoring and voltage measurement with an isolated acquisition system for this automotive battery pack application. In this design, the

Request Quote

Battery Mgmt. System

Simultaneous Sampling of All Cells and current, Eliminate Load current Noise Programmable Battery Impedance Mismatch Compensation 4 Zone + On-Chip Accurate Temperature

Request Quote

512 Channels 3a 5v 5a 6a Energy Feedback Cylindrical Battery

3. Equipment using AVR single piece computer as the control center, with peripheral sampling circuit, can be controlled by the superior computer, when connected to the computer, can save

Request Quote

512 Channels 5v 3a 6a 18650 32140 21700 Battery Capacity

Key attributes Accuracy Class 0.1%FS Application Battery Cell, Test Battery Capacity Support Battery Other Voltage Range 10 mV ~ 5 V Place of Origin Guangdong, China Measuring

Request Quote

Understanding Measurement Accuracy Specifications for

In this white paper, you will learn how to define accuracy and error in the realm of test equipment, four ways to specify accuracy, and interpret an actual error versus a specified error.

Request Quote

The 4-Wire Measurement: Key to Accurate Battery

Precise battery measurements are essential to achieve reliable results. With 4-wire measurement, it is possible to eliminate cable resistance

Request Quote

Sources of Error with the Coulomb Counting Method

Current sensors can have an accuracy of better than 1%, but that depends on the type and on the measurement range. A battery pack designed for very high peak currents will

Request Quote

17-Cell Battery Monitoring Analog Front End With High Sampling Accuracy

A high voltage multiplexer of 17-cell battery monitoring analog front end (AFE) is adopted to acquire each cell voltage for accurate monitoring. Besides, a current compensation

Request Quote

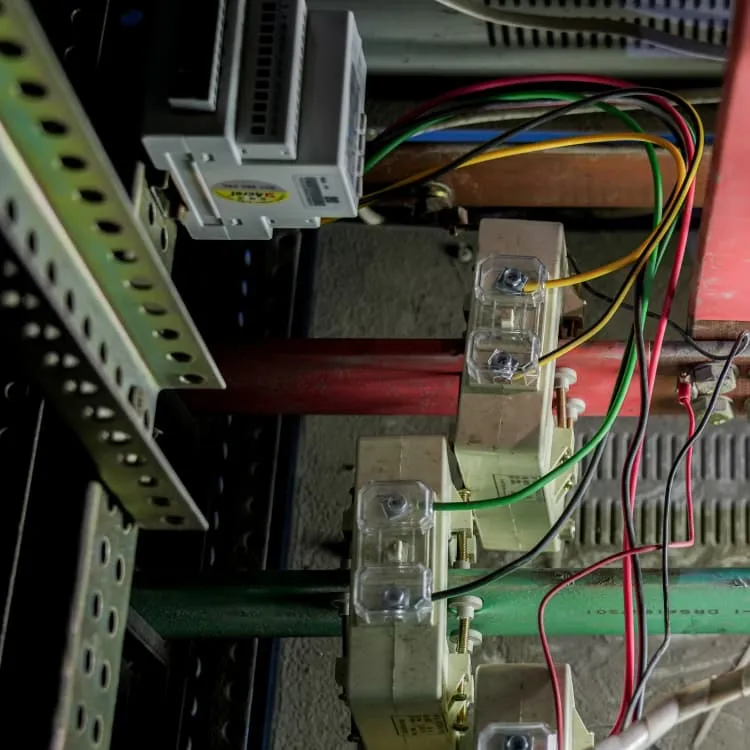

Battery cabinet current sampling

To achieve high-accuracy battery voltage measurement, a differentiated multi-channel high-voltage switch array and a battery sense structure with leakage current compensation are

Request Quote

How to Evaluate Battery Test Equipment

Current information in the lithium-ion battery charging system is important for system control and can be used for overload protection, constant current control

Request Quote

17-Cell battery monitoring analog front end with high sampling accuracy

A high voltage multiplexer of 17-cell battery monitoring analog front end (AFE) is adopted to acquire each cell voltage for accurate monitoring. Besides, a current compensation

Request Quote

Accurate Current Measurement in Modern Electronic Circuits

Introduction As power electronic switching techniques advance, there is an increased need to accurately measure current for feedback control and system monitoring. There are several

Request Quote

How to Evaluate Battery Test Equipment

Precision determines the level of noise/fluctuation present in the test equipment''s measurement. Precision also indicates the consistency and repeatability of the instrument''s measurement

Request Quote

(PDF) A Novel System for Measuring Alternating

The distributed signal sampling units simultaneously measure the voltage and current of all the series-connected battery cells in a module to

Request Quote

17-Cell battery monitoring analog front end with high sampling

A high voltage multiplexer of 17-cell battery monitoring analog front end (AFE) is adopted to acquire each cell voltage for accurate monitoring. Besides, a current compensation

Request Quote

Understanding Measurement Accuracy

In this white paper, you will learn how to define accuracy and error in the realm of test equipment, four ways to specify accuracy, and interpret an actual error

Request Quote

How to Design a Simple and Highly Integrated Battery

In this process, the current and voltage of the battery must be controlled accurately. It is usually required that the precision can reach 0.1%. Therefore, battery formation and test systems

Request Quote

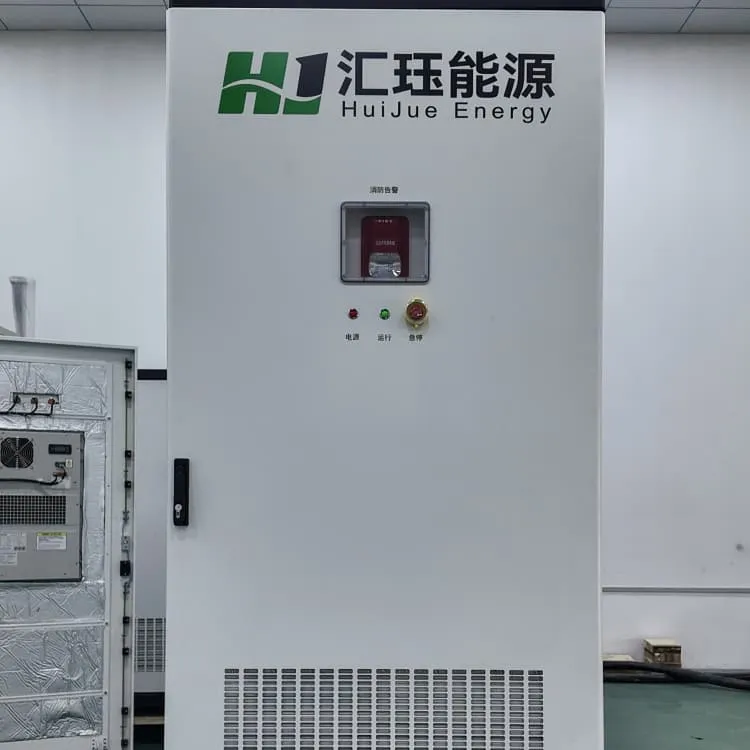

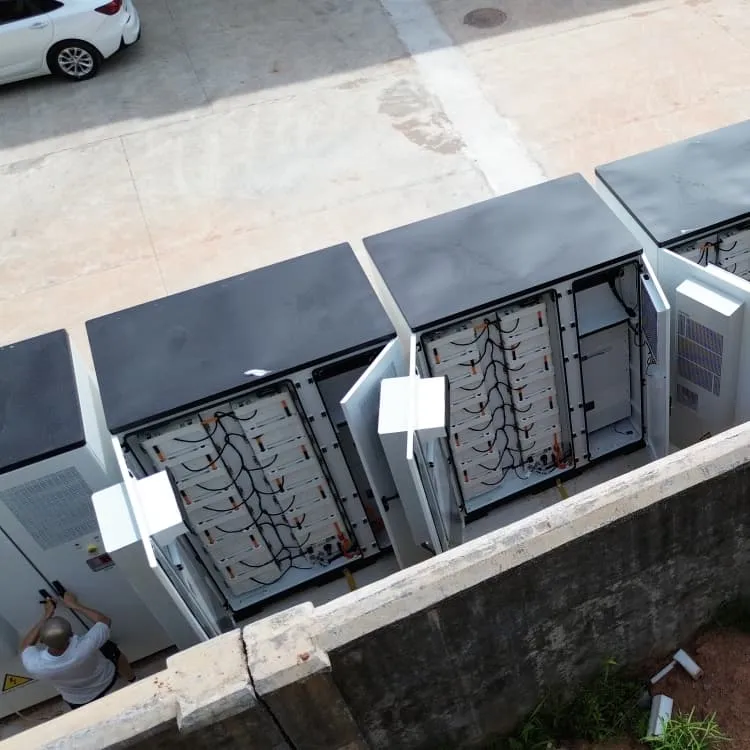

Battery Aging Cabinet

Introduction: The charging and discharging aging system mainly includes PC software, USB hub, router, and aging instrument. The core lies in the aging

Request Quote

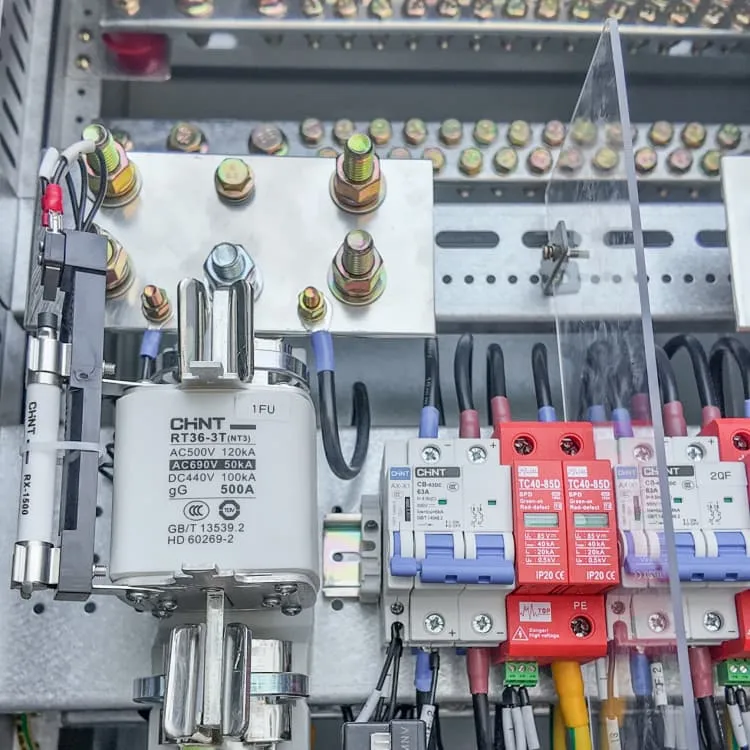

Battery Cabinet Current Limits | HuiJue Group E-Site

Why Current Management Defines Modern Energy Storage Success Have you ever wondered why battery cabinet current limits account for 43% of thermal runaway incidents in grid-scale

Request Quote

Battery Aging Cabinet,Battery Aging Machine,Battery

The aging cabinet is mainly used for testing the charging and discharging cycle of finished lithium batteries. The testing items include: battery charging

Request Quote

BQ76952: Sampling accuracy of current at the following frequencies

I found this description in the user manual: "with one output every 3 ms when the device is operating in NORMAL mode", Does this mean that it is possible to sample the

Request Quote

How To Choose The Battery Test Equipment? 5 Proven Tips

5 hours ago· 5. Battery Test Equipment Procurement checklist (quick reference) Does the unit meet required voltage/current precision across the full range? Is the sampling cadence

Request Quote

Simplify Voltage and Current Measurement in Battery Test

Voltage and current sensing are the two most significant measurements in battery test equipment systems. Furthermore, the most important parametric characteristics for this application is a

Request Quote

CN112611910A

The invention provides a battery current sampling device, which is applied to the technical field of current sampling and comprises the following components: the device comprises a current

Request QuoteFAQs 6

How can a high voltage multiplexer improve battery monitoring accuracy?

A high voltage multiplexer of 17-cell battery monitoring analog front end (AFE) is adopted to acquire each cell voltage for accurate monitoring. Besides, a current compensation scheme is proposed to tackle the current leakage in each channel to further improve the acquisition accuracy.

What factors affect battery testing accuracy?

The voltage and current detection accuracy are the most important parameters for battery testing system. There are three main factors that affect accuracy: Take care when selecting an operational amplifier and resistors. TI recommends selecting 0.1% resistors and operational amplifiers with low offset. Typically, a DAC corrects accuracy.

Are battery pack monitoring schemes accurate?

Although some battery pack monitoring schemes have increased the number of measurable channels in a chip for higher voltage battery packs, the issue of accuracy caused by the common mode voltage difference in each unit of series battery pack remains unsolved.

Which amplifier is necessary for high accuracy current shunt measurement?

The amplifier selection is highly dependent on the input signal and the sampling rate of the ADC. Referring to the discussion in Section 2.1.2, the current measurement accuracy is highly limited by the amplifier in this stage. Hence, an appropriate precision amplifier is necessary for high accuracy current shunt measurement.

What is battery test equipment?

Battery test equipment is used to verify battery pack functionality and performance prior to shipment to the customer. This application brief outlines three major functional tests that a battery tester performs while showing how to achieve the desired level of regulated error. ADC Figure 1. Traditional Battery Test Equipment Block Diagram

How to test a battery before it comes out?

The battery must be tested strictly before it comes out of the factory, and the battery test equipment is used to verify battery pack functionality and performance. For the most commonly used battery testing system in the market is the separation solution, which is a mature solution.

Related reading topics

- Lithium battery high current battery cabinet

- Energy storage cabinet station charging battery current

- Current loss rate of battery cabinet

- What is the discharge current of the battery cabinet

- Battery cabinet current algorithm formula

- Maximum current for charging and discharging the battery cabinet

- Price of high current battery for energy storage cabinet

- How to calibrate the battery cabinet current