Production of 6-parallel and 7-series lithium battery packs

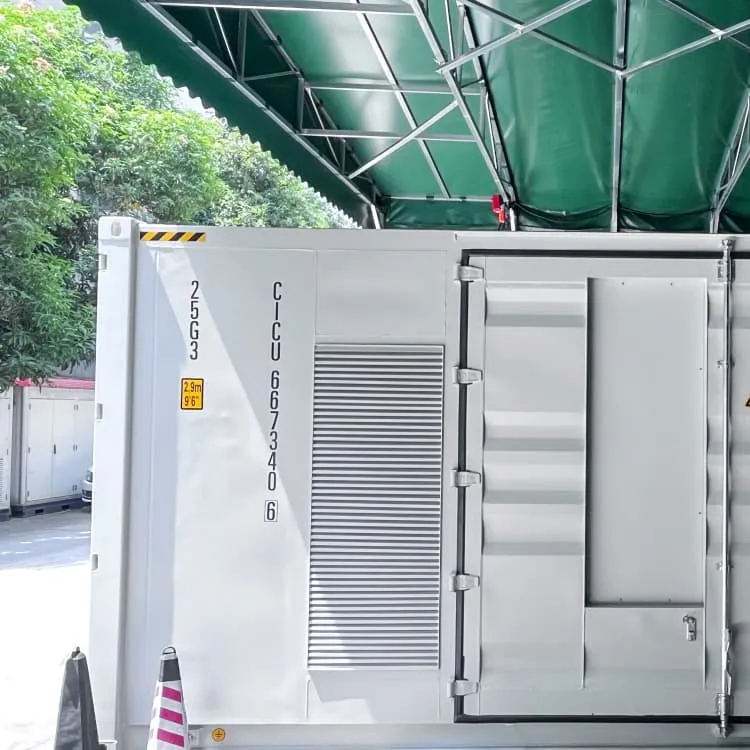

Welcome to our dedicated page for Production of 6-parallel and 7-series lithium battery packs! Here, we have carefully selected a range of videos and relevant information about Production of 6-parallel and 7-series lithium battery packs, tailored to meet your interests and needs. Our services include high-quality solar container products and containerized PV solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to Production of 6-parallel and 7-series lithium battery packs, including cutting-edge solar container systems, advanced containerized PV solutions, and tailored solar energy storage applications for a variety of industries. Whether you're looking for large-scale utility solar projects, commercial containerized systems, or mobile solar power solutions, we have a solution for every need. Explore and discover what we have to offer!

Series and Parallel Configuration of Lithium Battery

Four 18650 Lithium-ion cells of 3400 mAh can connect in series and parallel as shown to get 7.2 V nominal and 12.58 Wh. The slim cell allows

Request Quote

Integration issues of lithium-ion battery into electric vehicles

In EVs, Lithium-ion cells are connected in series and/or parallel to deliver the required power to the traction motor and auxiliary systems. However, due to the operating

Request Quote

Ultimate Power: Lithium-Ion Batteries In Series

The common notation for battery packs in parallel or series is XsYp – as in, the battery consists of X cell "stages" in series, where each stage

Request Quote

Production Process of Battery Modules and Battery

PDF | On Oct 25, 2023, Heiner Heimes and others published Production Process of Battery Modules and Battery Packs | Find, read and cite all the research

Request Quote

Engineering Guide to Custom Series-Parallel LiFePO4 Battery Packs

How to design, test and procure custom LiFePO4 battery pack designs (series-parallel): BMS specs, acceptance tests & RFP checklist.

Request Quote

Understanding Battery Pack Configurations: Series vs. Parallel

Battery pack configurations determine how much power a battery can provide and for how long. Whether you''re choosing a battery pack for an electric vehicle, a robotics project,

Request Quote

PRODUCTION PROCESS OF BATTERY MODULES AND

The publication "Production process of a lithium-ion battery cell" provides a comprehensive process overview of the production of different battery cell formats from electrode

Request Quote

Lithium Battery PACK Production Line Processes and

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks,

Request Quote

Lithium-ion Battery Pack Manufacturing Process & Design

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Request Quote

Series and Parallel, which is the first when assembling

Series and Parallel, which is the first when assembling lithium battery packs? In the design of the battery modules, whether to connect them

Request Quote

Battery Manufacturing Process: Materials, Production & Test

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process,

Request Quote

EV battery : serie vs. parallel cells and modules

Challenges in setups with parallel cells / modules and packs in EV conversions. Do''s and don''ts for more battery capacity (kWh) explained. Don''t overcharge.

Request Quote

Integrated balancing method for series‐parallel battery packs

Due to their advantages of high‐energy density and long cycle life, lithium‐ion batteries have gradually become the main power source for new energy vehicles [1,2]. Because of the low

Request Quote

What Is the Process of Lithium-Ion Battery Pack Assembly Production

So, what are the process flows of a lithium battery pack production line? Here, we break down the primary steps involved in this intricate process. Each step is crucial to

Request Quote

Production Line Guide | CHISAGE Battery Pack

Considering the safety, stability and cost-effectiveness, our company mainly produces lithium iron phosphate household batteries and

Request Quote

How to Build a Lithium Ion Battery Pack: Expert Guide for Engineers

Production reached 2.55 billion 18650 cells. The 21700 cell (21mm diameter, 70mm length) provides approximately 50% greater capacity than the 18650 for discharge rates up to

Request Quote

Production Process of Battery Modules and Battery Packs

PDF | On Oct 25, 2023, Heiner Heimes and others published Production Process of Battery Modules and Battery Packs | Find, read and cite all the research you need on ResearchGate

Request Quote

Production requirements of lithium battery PACK manufacturers

Lithium battery processing, production requirements of lithium battery PACK manufacturers. The process of assembling lithium battery cells into groups is called PACK,

Request Quote

Lithium Battery Assembly: Cell Stack Setup Tips

Part 1. What is a cell stack in a lithium battery? A cell stack is a collection of individual battery cells organized and connected to form a battery

Request Quote

BATTERY MODULE AND PACK ASSEMBLY PROCESS

Based on the brochure "Lithium-ion battery cell production process", this brochure schematically illustrates the further processing of the cell into battery modules and finally into a battery pack.

Request Quote

Optimal fast charging strategy for series-parallel configured lithium

The limited charging performance of lithium-ion battery (LIB) packs has hindered the widespread adoption of electric vehicles (EVs), due to the complex arrangement of numerous

Request Quote

Handbook On Lithium Battery Pack Design

The environment in which the battery pack is used and the electrical connection of the individual cells (series or parallel) are two key considerations when designing a battery pack and working

Request Quote

Production requirements of lithium battery PACK

Lithium battery processing, production requirements of lithium battery PACK manufacturers. The process of assembling lithium battery cells

Request Quote

Lithium-ion Battery Module and Pack Production Line Process Flow

The lithium-ion battery module and pack line is a key component in the field of modern battery technology. Its high degree of automation and rigorous process flow ensure

Request Quote

Management of imbalances in parallel-connected lithium-ion battery packs

This paper investigated the management of imbalances in parallel-connected lithium-ion battery packs based on the dependence of current distribution on cell chemistries,

Request Quote

Lithium-ion Battery Module and Pack Production Line

The lithium-ion battery module and pack line is a key component in the field of modern battery technology. Its high degree of automation and

Request Quote

Lithium Battery PACK Production Line Processes and Equipment

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks, utilizing equipment such as laser

Request Quote

Production Line Guide | CHISAGE Battery Pack Process Flow

Considering the safety, stability and cost-effectiveness, our company mainly produces lithium iron phosphate household batteries and industrial and commercial batteries.

Request Quote

Battery Pack Design of Cylindrical Lithium-Ion Cells and

The parameters of the battery pack must match the requirements of maximum power, voltage, maximum current, and mileage. The nominal voltage of the battery cell is 3.6 V. Assuming that

Request Quote

What Is the Process of Lithium-Ion Battery Pack

So, what are the process flows of a lithium battery pack production line? Here, we break down the primary steps involved in this intricate process.

Request QuoteFAQs 6

What is the production process of lithium-ion battery cells?

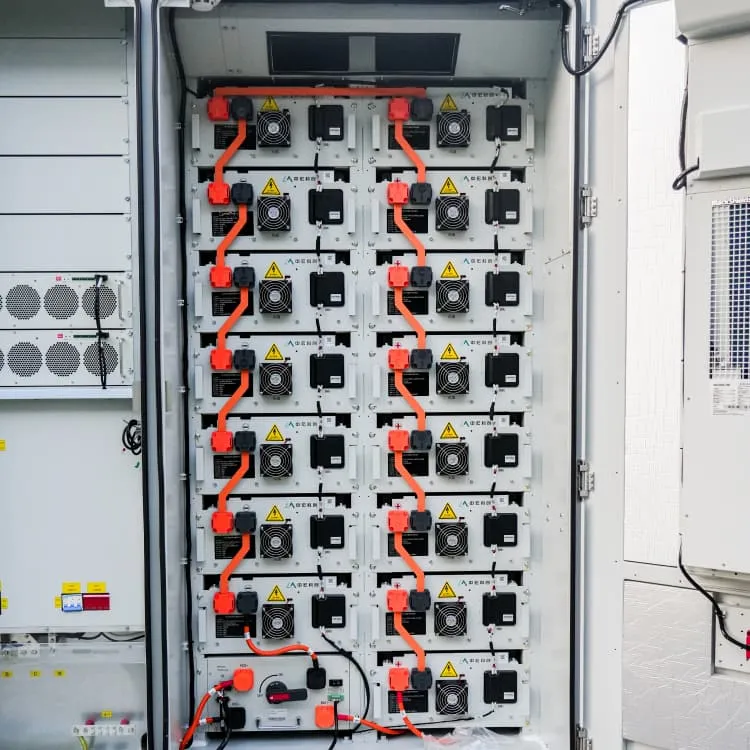

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

What is a lithium-ion battery module & pack production line?

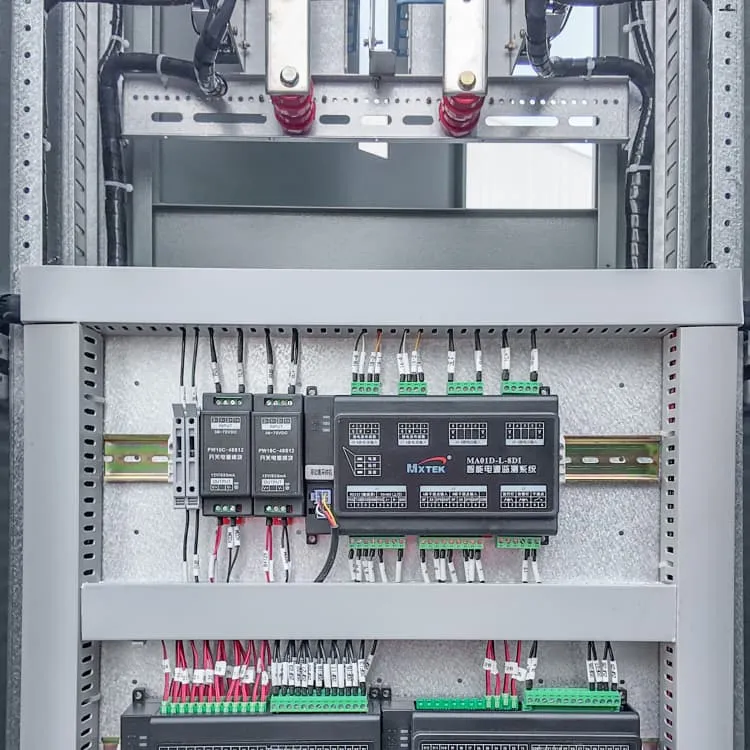

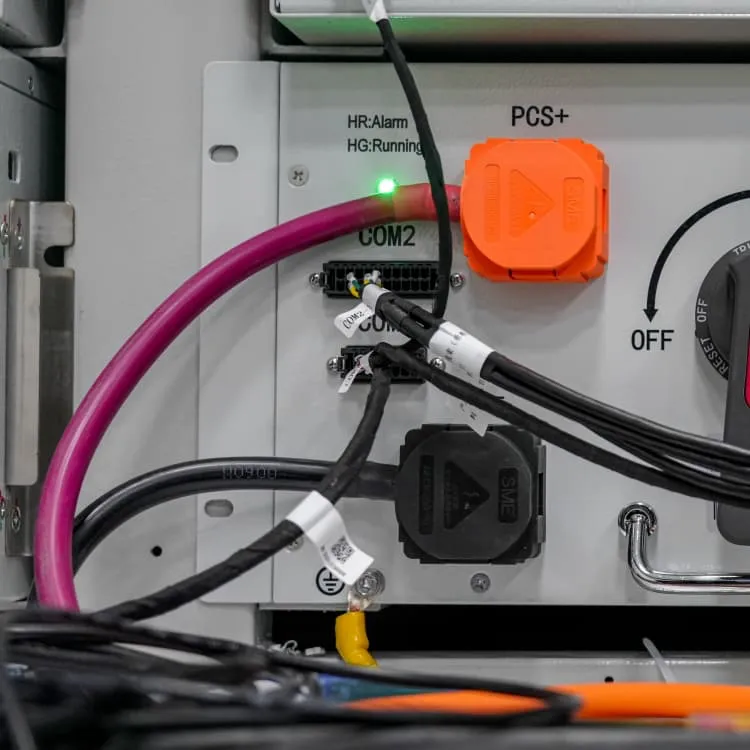

The lithium-ion battery module and pack production line is a complex system consisting of multiple major units and associated equipment that work in concert to achieve high quality lithium-ion module and pack production.

Why should you choose a lithium-ion battery module & pack line?

The whole system has no leakage of electricity, water, liquid or gas, which ensures the safety and stability of the production process. The lithium-ion battery module and pack line is a key component in the field of modern battery technology. Its high degree of automation and rigorous process flow ensure high quality and efficiency in production.

What are the production processes of a battery pack?

Outer Packaging: Provides physical protection. Output Interfaces: For connecting the battery pack with external devices. Production processes cover cell selection and grouping, welding, assembly, aging testing, inspection, and packaging. Assembly Production Line The process flow of the PACK production line includes:

What is the process chain for the production of battery modules?

, this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain Overview of the production sequence from cell to system

What is battery pack assembly?

The battery pack assembly is the process of assembling the positive electrode, negative electrode, and diaphragm into a complete battery. This involves placing the electrodes in a cell casing, adding the electrolyte, and sealing the cell.

Related reading topics

- Balanced production of lithium battery packs

- Production of single lithium battery packs

- Lithium battery site cabinet production base station power generation

- Lithium Battery Station Cabinet Production Management

- Lithium battery production equipment in Vaduz

- Lithium battery energy storage cabinet production principle

- Lithium battery inverter production

- Automated production of lithium battery cabinets in Botswana