Photovoltaic panels silicon wafers and batteries

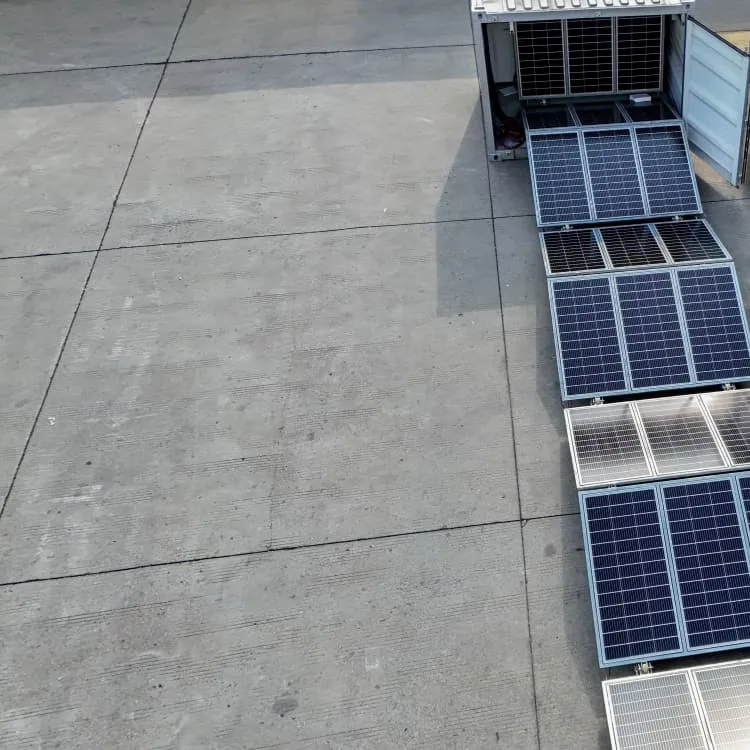

Welcome to our dedicated page for Photovoltaic panels silicon wafers and batteries! Here, we have carefully selected a range of videos and relevant information about Photovoltaic panels silicon wafers and batteries, tailored to meet your interests and needs. Our services include high-quality solar container products and containerized PV solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to Photovoltaic panels silicon wafers and batteries, including cutting-edge solar container systems, advanced containerized PV solutions, and tailored solar energy storage applications for a variety of industries. Whether you're looking for large-scale utility solar projects, commercial containerized systems, or mobile solar power solutions, we have a solution for every need. Explore and discover what we have to offer!

Solar Cell Production: from silicon wafer to cell

This article explains in detail the production process from sliced silicon wafer disks to the final ready-to-assemble solar cell.

Request Quote

Solar Panel Manufacturing Process: Step-by-Step Guide

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Request Quote

Photovoltaic Cell Generations and Current Research

The purpose of this paper is to discuss the different generations of photovoltaic cells and current research directions focusing on their development and

Request Quote

Advance of Sustainable Energy Materials: Technology Trends for Silicon

Modules based on c-Si cells account for more than 90% of the photovoltaic capacity installed worldwide, which is why the analysis in this paper focusses on this cell type.

Request Quote

Fabricating Different Types of Photovoltaic Cells

Crystalline silicon cell wafers are formed in three primary types: monocrystalline, polycrystalline, and ribbon silicon. Each type has advantages and disadvantages in terms of

Request Quote

Solar Cell Production: from silicon wafer to cell

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Request Quote

Solar Panel Construction

Solar panels use photovoltaic cells, or PV cells for short, made from silicon crystalline wafers similar to the wafers used to make computer

Request Quote

Cadmium Telluride Solar Panels Vs. Silicon:

Explore the efficiency, cost, and environmental advantages of cadmium telluride (CdTe) solar panels over silicon in this 2025 comparison.

Request Quote

Solar Photovoltaic Manufacturing Basics

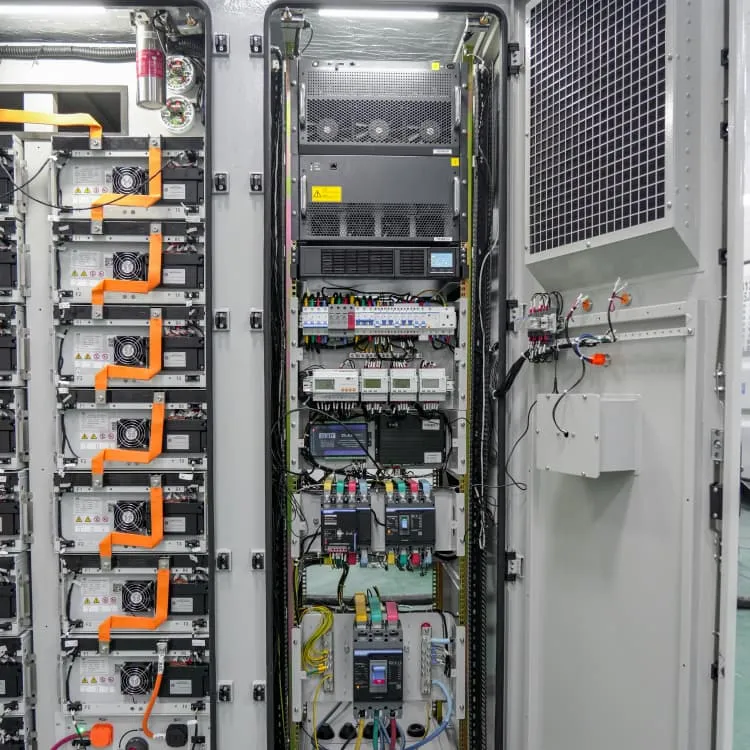

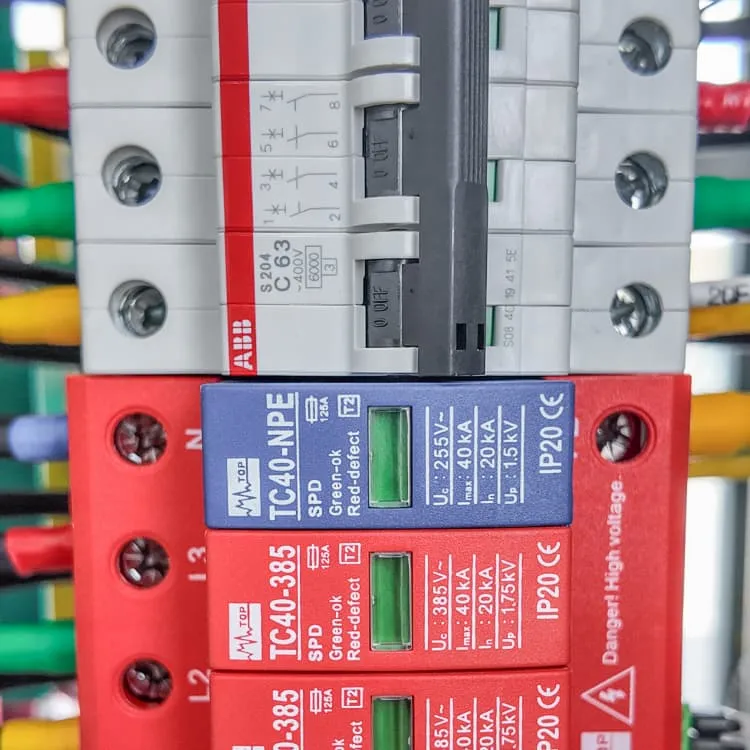

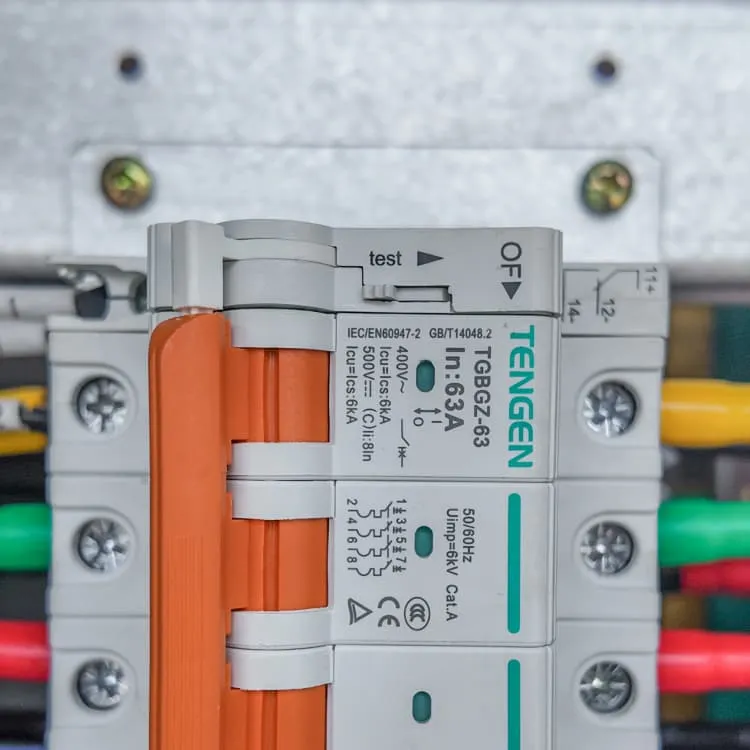

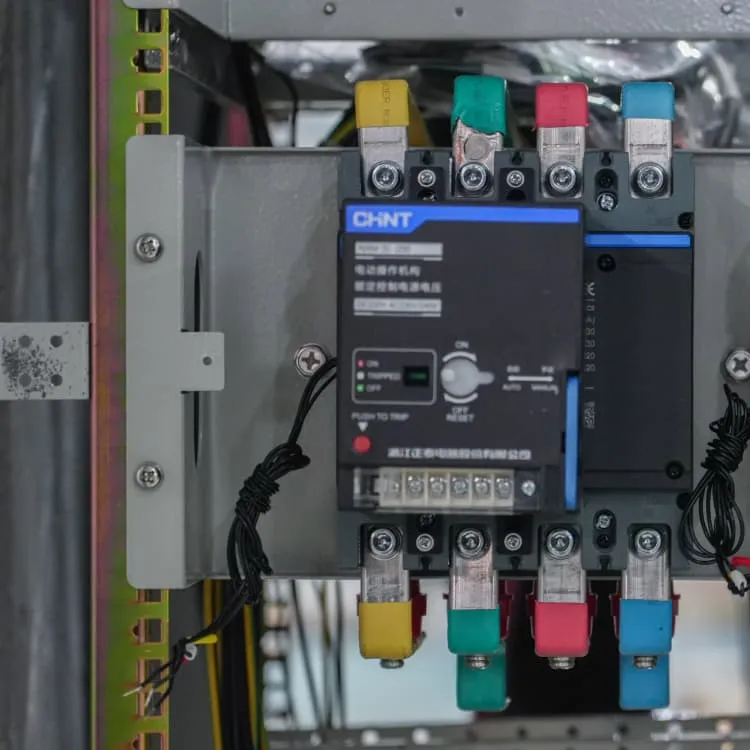

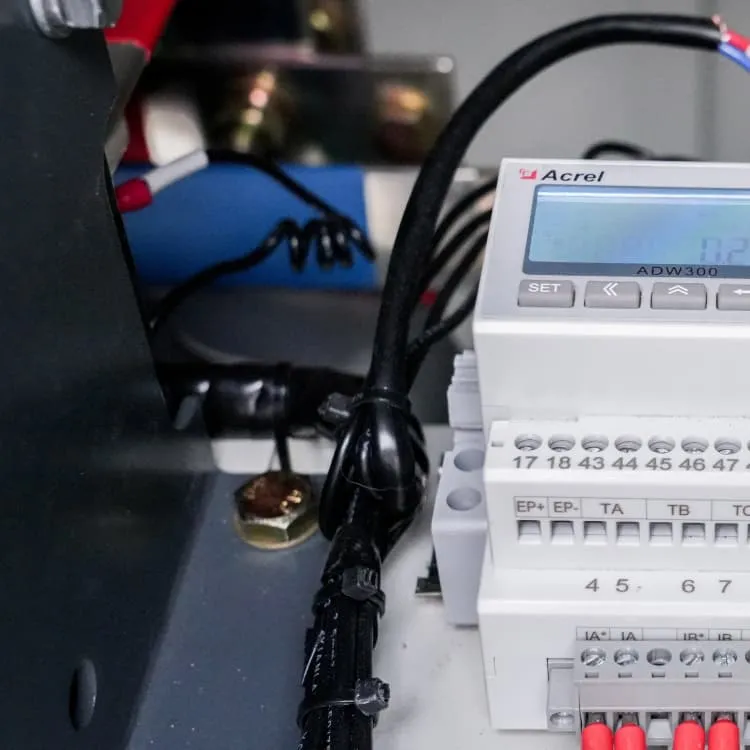

Those systems are comprised of PV modules, racking and wiring, power electronics, and system monitoring devices, all of which are manufactured. Learn how PV works.

Request Quote

New Study Explores Reusing Solar Panel Silicon for High

In a recently published study, UVA Environmental Institute faculty affiliates Gary Koenig and Mool Gupta, alongside co-authors, explore how silicon from decommissioned solar

Request Quote

Solar Wafer

A solar wafer is a thin slice of a crystalline silicon (semiconductor), which works as a substrate for microeconomic devices for fabricating

Request Quote

Solar panels face recycling challenge

Producing new wafers accounts for about half the energy used to make a solar module, so reusing silicon from old panels could dramatically reduce the

Request Quote

Solar Silicon Wafer Market | Global Market Analysis Report

The solar silicon wafer market occupies a targeted yet critical share across several supply and equipment value chains. Within the solar photovoltaic module components market,

Request Quote

What Is a Silicon Wafer for Solar Cells?

Silicon wafers are by far the most widely used semiconductors in solar panels and other photovoltaic modules. P-type (positive) and N-type (negative) wafers are manufactured and

Request Quote

Solar Cell Production: from silicon wafer to cell

Producers of solar cells from silicon wafers, which basically refers to the limited quantity of solar PV module manufacturers with their own wafer

Request Quote

How Do Photovoltaic Cells Work? | EcoFlow ES

N-Type PV cells are doped with phosphorus, antimony, or arsenic to create an intentional imbalance that favors electrons at the atomic level. P-Type semiconductors add a dopant like

Request Quote

Fabricating Different Types of Photovoltaic Cells

Crystalline silicon cell wafers are formed in three primary types: monocrystalline, polycrystalline, and ribbon silicon. Each type has advantages

Request Quote

A review of end-of-life crystalline silicon solar photovoltaic panel

This massive EOL volume will become a global burden on the environment and the economy [9]. According to the manufacturing technology of silicon wafers, solar PV panels can

Request Quote

Powering the Future: Inside the Solar PV Cell Manufacturing

Explore the critical stages of silicon purification, wafer fabrication, cell processing, and module assembly, gaining a deep understanding of the scientific principles and

Request Quote

Solar Value Chain – Panel Supply Steps | Bernreuter

The silicon cylinder or block is called ingot; it is sawn into square bricks and those are sliced into thin silicon wafers. More than 90% of all solar cells are made of

Request Quote

Photovoltaic Cell Generations | Encyclopedia MDPI

The primary role of a photovoltaic cell is to receive solar radiation as pure light and transform it into electrical energy in a conversion process called the photovoltaic effect.

Request Quote

How Are Solar Cells Made? A Complete Guide To

Discover how are solar cells made in our in-depth guide. Dive into the detail of solar panel production, from raw materials to finished product.

Request Quote

Solar Photovoltaic Manufacturing Basics

Those systems are comprised of PV modules, racking and wiring, power electronics, and system monitoring devices, all of which are manufactured.

Request Quote

Photovoltaic Cell Generations | Encyclopedia MDPI

The primary role of a photovoltaic cell is to receive solar radiation as pure light and transform it into electrical energy in a conversion process called the

Request Quote

Powering the Future: Inside the Solar PV Cell

Explore the critical stages of silicon purification, wafer fabrication, cell processing, and module assembly, gaining a deep understanding of the

Request Quote

Photovoltaic Cell Generations and Current Research Directions

The purpose of this paper is to discuss the different generations of photovoltaic cells and current research directions focusing on their development and manufacturing technologies. The

Request Quote

The Process of Making Solar Cells: From Silicon to

The solar cell production industry is a complex web of different players, each with their unique roles. Solar PV module production lies at the

Request Quote

America''s largest silicon solar cell manufacturer opens

The cells first start as gray silicon wafers and go through many steps on their seven-hour journey to finished product — things like diffusion,

Request Quote

Solar Wafer

A solar wafer is a thin slice of a crystalline silicon (semiconductor), which works as a substrate for microeconomic devices for fabricating integrated circuits in photovoltaics (PVs)

Request Quote

Flexible silicon solar cells with high power-to-weight ratios

A study reports a combination of processing, optimization and low-damage deposition methods for the production of silicon heterojunction solar cells

Request Quote

PV Solar Cell Manufacturing Process & Equipment

The rise of sustainable energy solutions has thrust solar power into the limelight as a pivotal force in the global energy transition. Central to this solar revolution

Request QuoteRelated reading topics

- What is the price of silicon wafers in photovoltaic panels

- Photovoltaic panels and silicon wafers

- Togo photovoltaic silicon panels

- What are Sierra Leone monocrystalline silicon photovoltaic panels

- What are polycrystalline silicon photovoltaic panels

- Are the batteries under the photovoltaic panels useful

- Photovoltaic panels and lithium batteries connected

- Azerbaijan polycrystalline silicon solar photovoltaic panels