Open a company to produce monocrystalline silicon photovoltaic panels

Welcome to our dedicated page for Open a company to produce monocrystalline silicon photovoltaic panels! Here, we have carefully selected a range of videos and relevant information about Open a company to produce monocrystalline silicon photovoltaic panels, tailored to meet your interests and needs. Our services include high-quality solar container products and containerized PV solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to Open a company to produce monocrystalline silicon photovoltaic panels, including cutting-edge solar container systems, advanced containerized PV solutions, and tailored solar energy storage applications for a variety of industries. Whether you're looking for large-scale utility solar projects, commercial containerized systems, or mobile solar power solutions, we have a solution for every need. Explore and discover what we have to offer!

Advances in crystalline silicon solar cell technology for industrial

Crystalline silicon photovoltaic (PV) cells are used in the largest quantity of all types of solar cells on the market, representing about 90% of the world total PV cell production in

Request Quote

How to make solar panels from monocrystalline silicon

In summation, the journey of creating monocrystalline silicon solar panels is a detailed and intricate process, encompassing numerous steps that ensure high efficiency and

Request Quote

What Is a Monocrystalline Solar Panel? Definition,

A monocrystalline (mono) solar panel is a type of solar panel that uses solar cells made from a single silicon crystal. The use of a single silicon

Request Quote

What are solar panels made of? [Materials

What materials are solar panels made of? This guide focuses on single crystal (c-Si) solar photovoltaic (PV) technology, also known as

Request Quote

Manufacturing Business of Solar Panel (Polycrystalline and

As a result of the constant shift toward renewable energy, the worldwide solar panel industry is booming. Due to the increased adoption of solar power capacity, the EU, Asia

Request Quote

Properties of polycrystalline silicon cell

This block is then sliced into ingots and further cut into thin wafers similar to those used in monocrystalline solar cells. The wafers are cleaned

Request Quote

Efficiency of Monocrystalline Solar Panels: A

Understanding Monocrystalline Solar Panels Monocrystalline solar panels are considered the most efficient type of solar panel in the market.

Request Quote

What Are Solar Panels Made Of and How Are They

Answering that question means understanding how solar energy works, how solar panels are manufactured, and what the parts of a solar panel

Request Quote

5 Steps For Monocrystalline Silicon Solar Cell Production

The Czochralski (CZ) method dominates production, accounting for 85% of global monocrystalline silicon supply, due to its balance of cost (~$15-20/kg) and quality.

Request Quote

How to Manufacture Solar Panel – A Complete Guide

Solar energy is becoming one of the most reliable and sustainable energy sources in the world. With the rising demand for clean energy, the

Request Quote

Manufacturing Business of Solar Panel (Polycrystalline and Monocrystalline)

As a result of the constant shift toward renewable energy, the worldwide solar panel industry is booming. Due to the increased adoption of solar power capacity, the EU, Asia

Request Quote

The Manufacturing Process of Solar Panels: From

Discover the fascinating journey of solar panel creation, as we unveil the intricate steps in the manufacturing process from raw materials to

Request Quote

Solar Manufacturing Cost Analysis | Solar Market

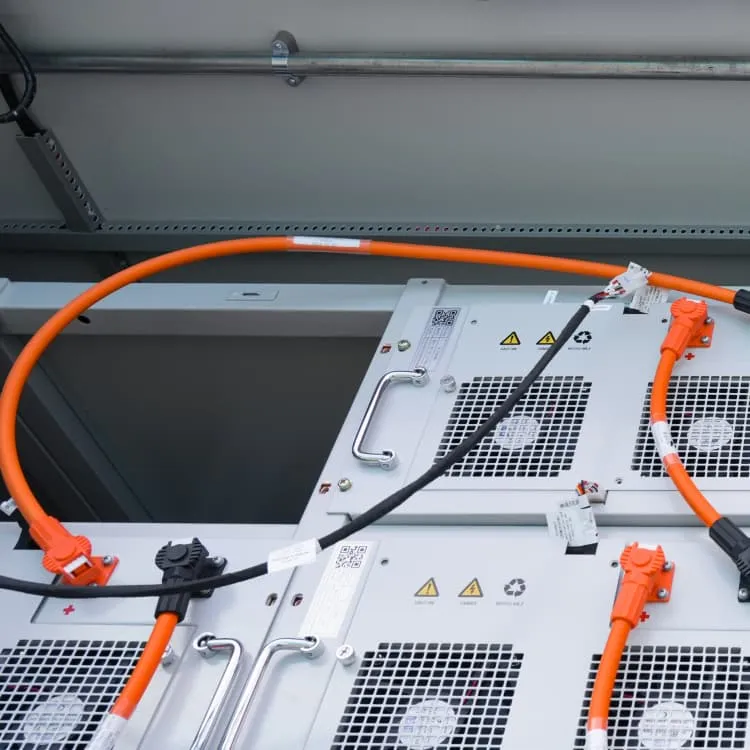

These manufacturing cost analyses focus on specific PV and energy storage technologies—including crystalline silicon, cadmium telluride,

Request Quote

How to make solar panels from monocrystalline silicon

In summation, the journey of creating monocrystalline silicon solar panels is a detailed and intricate process, encompassing numerous steps that

Request Quote

Advantages & Disadvantages of Monocrystalline Silicon Solar Panels

1. Monocrystalline solar panels are the most expensive. From a financial standpoint, a solar panel that is made of polycrystalline silicon (and in some cases thin-film)

Request Quote

Monocrystalline Solar Panel — Everything You Need To Know

A monocrystalline PV panel is a premium energy-producing panel consisting of smaller monocrystalline solar cells (60 to 72 cells). Their superior aesthetics and efficiency

Request Quote

Monocrystalline Silicon

So, if you''re in the market for a solar panel that offers high efficiency, consistent performance, and durability, Monocrystalline solar panels make a compelling case.

Request Quote

Monocrystalline Solar Panels

The article compares monocrystalline and polycrystalline solar panels in terms of their construction, efficiency, suitability for different applications, costs, lifespan, and temperature

Request Quote

Monocrystalline solar panels: a comprehensive guide

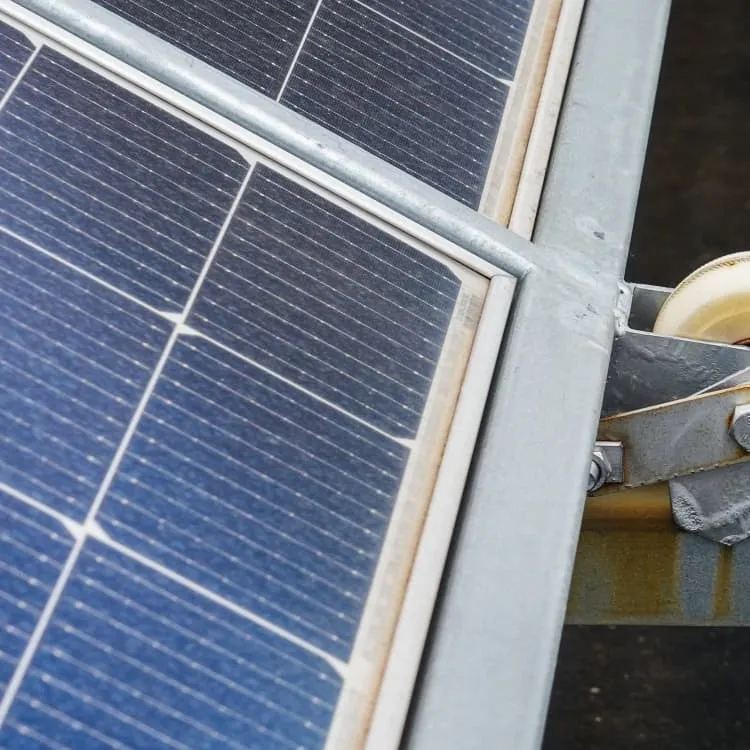

How is a monocrystalline solar panel made Monocrystalline panels are thin slabs typically composed of 30-70 photovoltaic cells assembled, soldered together, and covered by

Request Quote

Monocrystalline Solar Panels: Advantages and Disadvantages

8 Good Reasons Why Monocrystalline Solar Panels are the Industry Standard Monocrystalline photovoltaic electric solar energy panels have been the go-to choice for many years. They are

Request Quote

The Manufacturing Process of Solar Panels: From Raw Materials

Discover the fascinating journey of solar panel creation, as we unveil the intricate steps in the manufacturing process from raw materials to energy.

Request Quote

Powering the Future: Inside the Solar PV Cell Manufacturing

Join us as we unravel the secrets of PV cell manufacturing, empowering you with the knowledge to navigate the exciting world of renewable energy and contribute to a greener

Request Quote

Solar Panel Manufacturing Process: Step-by-Step Guide

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Request Quote

Powering the Future: Inside the Solar PV Cell

Join us as we unravel the secrets of PV cell manufacturing, empowering you with the knowledge to navigate the exciting world of

Request Quote

Comprehensive Guide to Monocrystalline Solar Panel

Monocrystalline Solar Panels vs Polycrystalline Solar Panels Solar cells come in different types, with monocrystalline and polycrystalline being

Request Quote

Solar Photovoltaic Manufacturing Basics

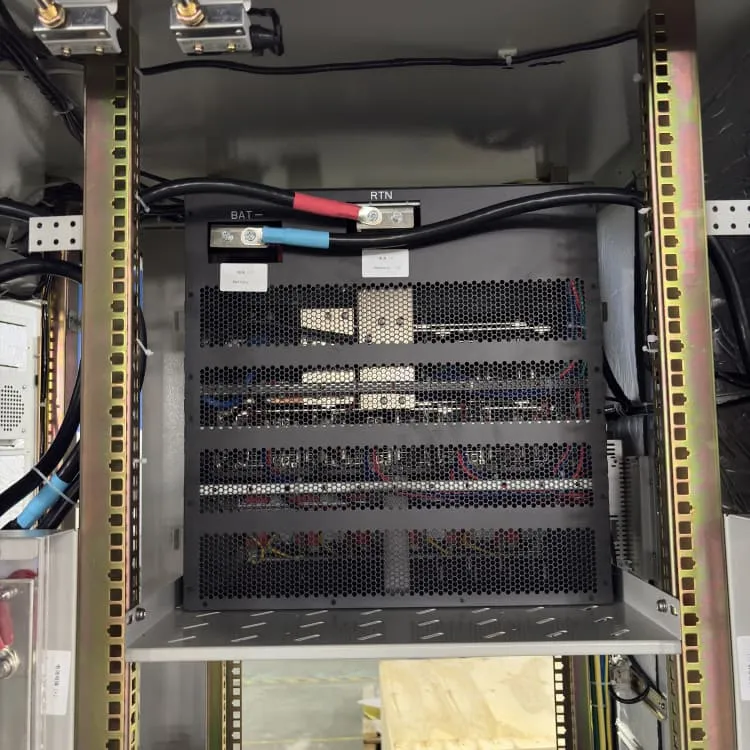

Most commercially available PV modules rely on crystalline silicon as the absorber material. These modules have several manufacturing steps that typically occur separately from each other.

Request Quote

How Monocrystalline Solar Cells Work

If you see a solar panel, the chances are it''s made of monocrystalline solar cells. They are by far the most widely used solar

Request Quote

Solar Manufacturing Cost Analysis | Solar Market Research & Analysis | NREL

These manufacturing cost analyses focus on specific PV and energy storage technologies—including crystalline silicon, cadmium telluride, copper indium gallium

Request QuoteFAQs 6

Is monocrystalline silicon a good material for solar panels?

Monocrystalline silicon, also known as single-crystal silicon, is a type of silicon that has a continuous crystal lattice structure. This unique structure makes it an ideal material for solar panels. But why, you may ask? Compared to its counterpart, polycrystalline silicon, monocrystalline silicon boasts a higher efficiency rate.

What makes monocrystalline solar panels unique?

Monocrystalline silicon, known for its sleek black aesthetic and high efficiency, stands apart from its competitors: polycrystalline and thin-film solar panels. But what exactly makes it unique? Monocrystalline panels are the top dog when it comes to efficiency, often reaching rates above 20%.

What is monocrystalline silicon?

Monocrystalline silicon, or ‘mono-si,’ is a type of silicon that serves as the fundamental material in the solar industry. The process to produce it, however, is no mean feat. Ever considered how a humble grain of sand transforms into a high-tech solar panel? The Czochralski Process stands at the heart of mono-si production.

Which raw materials are required to start solar panel manufacturing plant?

These are the raw materials required to start solar panel manufacturing plant. These are the machines required to start solar panel manufacturing business. Polysilicon is obtained from quartz with the application of carbon arc in an electric arc furnace.

How does Fenice energy make solar panels?

The intricate solar panel manufacturing process converts quartz sand to high-performance solar panels. Fenice Energy harnesses state-of-the-art solar panel construction techniques to craft durable and efficient solar solutions. The transformation of raw materials into manufacturing photovoltaic cells is a cornerstone of solar module production.

Which is better monocrystalline or polycrystalline solar cells?

Monocrystalline solar cells are made from a single continuous crystal structure, providing higher efficiency and better performance in low-light conditions. Polycrystalline cells, made from multiple silicon crystals, are generally less efficient but more cost-effective.

Related reading topics

- What are Sierra Leone monocrystalline silicon photovoltaic panels

- Monocrystalline silicon solar photovoltaic panels generate electricity on cloudy days

- Characteristics of monocrystalline silicon photovoltaic panels

- Uzbekistan photovoltaic panels monocrystalline silicon

- Middle East monocrystalline silicon photovoltaic panels

- Photovoltaic panels monocrystalline silicon or polycrystalline silicon

- What are the advantages of monocrystalline silicon photovoltaic panels

- Monocrystalline silicon portable photovoltaic panels