Battery cabinet current measurement principle

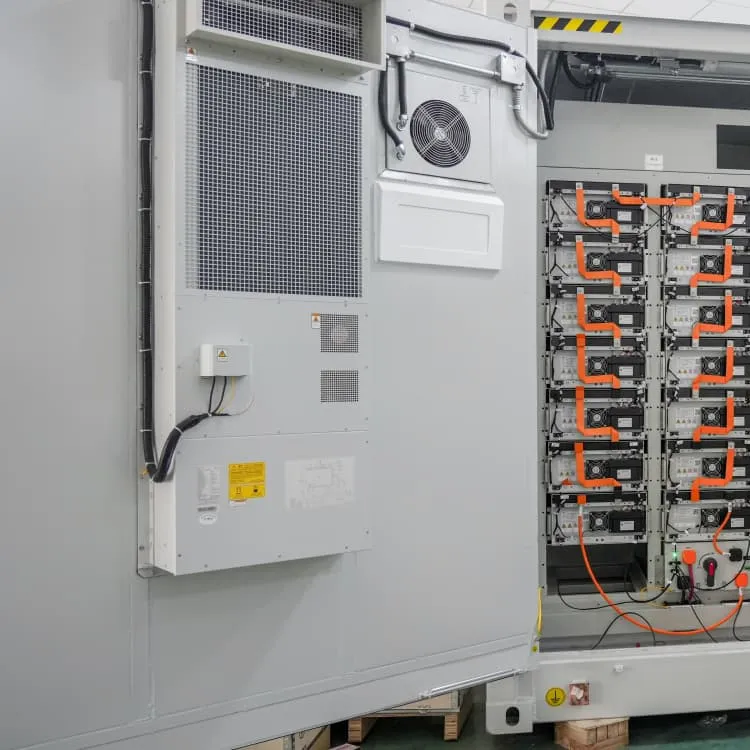

Welcome to our dedicated page for Battery cabinet current measurement principle! Here, we have carefully selected a range of videos and relevant information about Battery cabinet current measurement principle, tailored to meet your interests and needs. Our services include high-quality solar container products and containerized PV solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to Battery cabinet current measurement principle, including cutting-edge solar container systems, advanced containerized PV solutions, and tailored solar energy storage applications for a variety of industries. Whether you're looking for large-scale utility solar projects, commercial containerized systems, or mobile solar power solutions, we have a solution for every need. Explore and discover what we have to offer!

Current Sensor ICs in Battery Management Systems: A

Accurate current measurement by Current Sensor ICs allows for more efficient energy usage. The BMS can adjust the charge/discharge rates based on the current measurements, ensuring the

Request Quote

How to test the internal current of the battery cabinet

The Hioki BT3562 battery tester is designed to measure internal resistance using an AC current at a measurement frequency of 1 kHz, letting you accurately capture the internal resistance of

Request Quote

Battery Capacity Testing: Methods, Importance, and

Warranty and Compliance: Validates battery performance for warranty claims and industry standards. 2. Methods for Battery Capacity

Request Quote

DC power supply cabinet working principle and role

The product consists of AC power supply, rectifier, charger, battery pack, DC distribution system, circuit breaker, charger, battery, circuit breaker

Request Quote

Internal Resistance series. Part III: Which techniques

The principle is to apply an AC current – or potential if P-ACIR is used – at a single frequency, typically 1 kHz, and to measure the response in

Request Quote

UNDERSTANDING UPS SYSTEMS AND BATTERIES

The three main subsystems of a Uninterruptible Power Supply (UPS) are: Rectifier/charger – Converts alternating current (ac) into direct current (dc) used to maintain the battery at a

Request Quote

How to measure the current of energy storage battery cabinet

Measuring battery charge and capacity accurately is essential for optimizing industrial battery systems and ensuring reliable performance. By following best practices and

Request Quote

High-Side Current-Sense Measurement: Circuits and Principles

This application note describes the use of current sense amplifiers, differential amplifiers and instrumentation amplifiers to measure battery charge and discharge currents in portable

Request Quote

Current Sensing in Battery Management Systems

There are a variety of current sensing technologies that can monitor the status of an HEV or EV battery. The solution varies with the voltage and capacity of the battery.

Request Quote

Understanding Amps: How to Measure and Calculate

Measuring and calculating amps for electronics involves understanding the relationship between volts, watts, and current (amps).

Request Quote

Making High Quality Open Circuit Voltage Measurements on

OCV During Charging and Discharging Battery charging includes 2 steps Constant Current (CC): Battery is charged with a constant current rate defined by the C-rate Constant Voltage (CV):

Request Quote

Principles and Case Study Analysis of GITT Testing

This article explains the Galvanostatic Intermittent Titration Technique (GITT) principle and its application. GITT uses controlled current

Request Quote

How to Measure Current in a Circuit: The Essential

To measure current in a circuit, use an oscilloscope or a multimeter in series with the component. Learn the step-by-step guide and tips for accurate readings.

Request Quote

Microsoft Word

The battery cabinet is equipped with narrow pallet jack or forklift access openings in the front and rear of the cabinet. Move the equipment into the desired location and set in place.

Request Quote

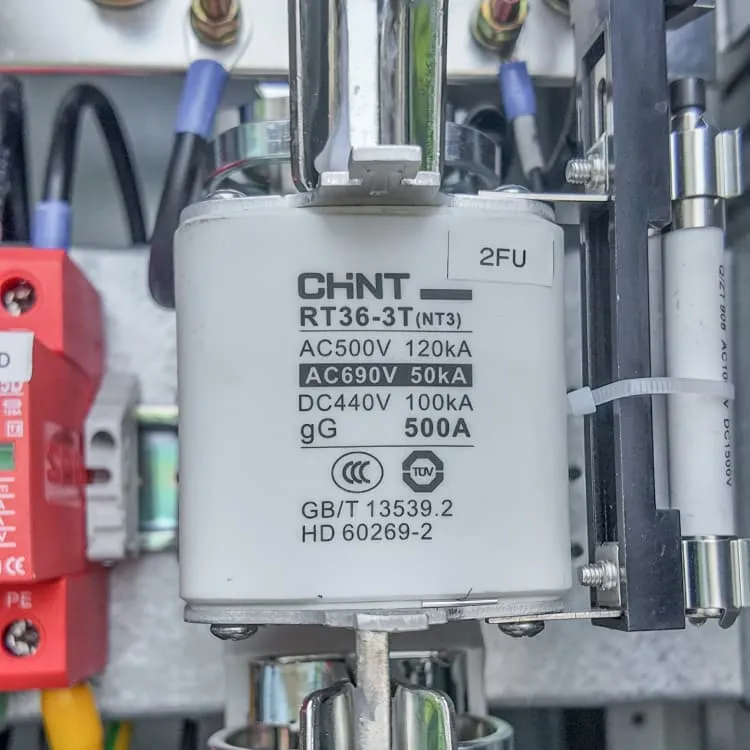

Acrel Hall Current Sensor in Battery Cabinet Monitoring

When the battery is charged and discharged, there are strict requirements on the charge and discharge current. This paper introduces the

Request Quote

Battery monitoring current sensors: The fluxgate concept

In this paper a new measurement principle based on a technology of type ldquofluxgaterdquo [1] is presented, which allows reaching a wide measurement range while

Request Quote

Application of Hall Current Sensor in Battery Cabinet Monitoring

When the battery is charged and discharged, there are strict requirements on the charge and discharge current. This paper introduces the realization of the battery charge and discharge

Request Quote

Battery Management Systems (BMS)

It involves measuring the flow of electrical charge into and out of the battery over time. Coulomb counting requires a current sensor to measure the current flowing into or out of the battery,

Request Quote

Acrel Hall Current Sensor in Battery Cabinet Monitoring

When the battery is charged and discharged, there are strict requirements on the charge and discharge current. This paper introduces the realization of the battery charge and

Request Quote

Application of Hall Current Sensor in Battery Monitoring System

Hall current sensor is a kind of magnetic field sensor based on Hall effect. When the primary side current (IP) flows through a long wire, a magnetic field is generated around

Request Quote

Internal Resistance series. Part III: Which techniques

The principle is to apply an AC current – or potential if P-ACIR is used – at a single frequency, typically 1 kHz, and to measure the response in voltage (or current).

Request Quote

High-Side Current-Sense Measurement: Circuits and Principles

Current measurement (monitoring current flow into and out of electronic circuits) is an essential skill in the designer''s repertoire and necessary in a wide range of applications. Examples

Request Quote

Low-side current sensing

What is low-side current sensing? What is the definition? • Low-side current sensing is a technique used to measure the current flowing through a load by placing a sensing resistor

Request Quote

Battery module current measurement. (a) Principle of

Download scientific diagram | Battery module current measurement. (a) Principle of mixed analog–digital control for the microwave generator frequency to trace

Request Quote

Step-by-Step Battery Capacity Testing Procedure

With our step-by-step procedure, you''ll learn how to precisely evaluate battery capacity. Discover key tools, techniques, & best practices for

Request QuoteFAQs 6

How to monitor the status of an EV battery?

There are a variety of current sensing technologies that can monitor the status of an HEV or EV battery. The solution varies with the voltage and capacity of the battery. As shown in Figure 1, there are two main locations where you can measure current: top of stack (high-side sensing) and bottom of stack (low-side sensing). Figure 1.

Why is current measurement important?

Current measurement (monitoring current flow into and out of electronic circuits) is an essential skill in the designer's repertoire and necessary in a wide range of applications.

How do ICS measure high-side current?

Another approach to high-side current measurement is represented by ICs that contain all functions necessary to perform the measurement. They sense high-side currents in the presence of common-mode voltages as high as 32V and provide a ground-referenced current- or voltage-source output that is proportional to the current of interest.

What is the future of battery and energy storage?

The field of battery and energy storage continues to grow exponentially with the development of consumer electronics and electric vehicles, among other key technologies.

How important is battery management in a car?

With the rapid growth of HEVs and EVs in the automotive market, systems such as battery management become significant. Take, for instance, your cellphone’s battery. You’re constantly checking its status to ensure that you can use your phone throughout the day. Now translating this to a car, imagine how crucial such information becomes.

How can laboratories improve battery performance and gain competitive advantage?

As a result, laboratories and industry are constantly looking to find new ways of improving battery performance and gaining competitive advantage, notably via reliability and longer battery life. They also need to understand and quantify battery degradation during its cycle life.

Related reading topics

- What is the principle of battery cabinet current algorithm

- Lithium battery high current battery cabinet

- Energy storage cabinet station charging battery current

- Energy Storage Battery Cabinet Expansion Principle

- How to measure the current in lithium battery station cabinet

- Battery cabinet current algorithm formula

- Battery cabinet current sampling accuracy

- What is the principle of integrated battery cabinet technology